The Ultimate Guide to Industrial Chillers 2022

The Definitive Guide - How do Industrial Water Chillers Work?

Industrial-commercial water chillers play a vital role in cooling buildings and industrial processes of all types. Whether the building interior space is for office use, manufacturing, medical-laboratory-hospital use, residential, institutional, chiller systems provide an effective method of removing excess heat and providing a temperature-controlled environment.

The primary function of a chiller system is to remove heat from an interior space and transfer it to the exterior. This is particularly important in industrial settings, where processes from manufacturing operations, for example, create large amounts of excess heat, which can negatively impact process performance and efficiency, or create uncomfortable interior conditions.

These might include burning or heating of raw materials, friction, and machinery use. The removal of this heat is necessary to keep systems running properly and efficiently. Such industrial process chillers differ from the HVAC systems found in residential or commercial settings. Following is a summary of their main components, and how industrial water chillers work.

How Industrial Water Chillers Work

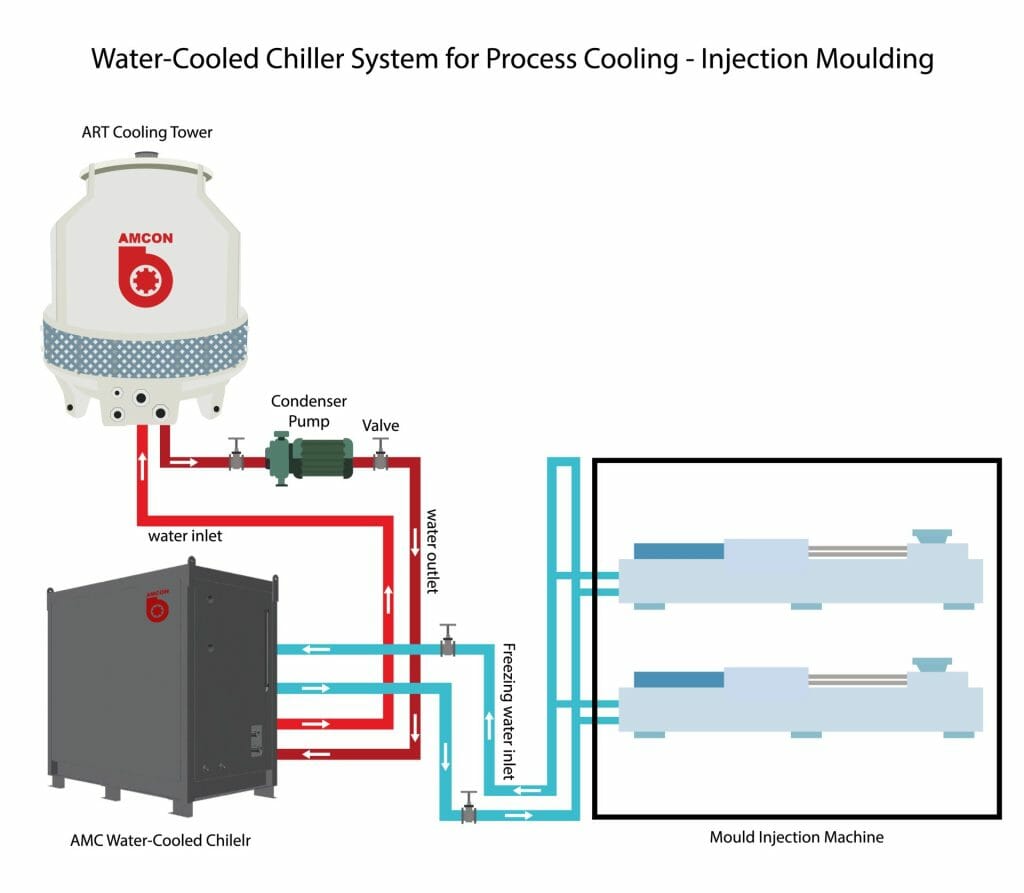

Chillers work by sending water to whatever process needs cooling. The water extracts the heat from the source; the warmed water is then sent to the chiller. A portion of the warmed water is transferred into the atmosphere as vapor. To make the complete cycle happen, four main components are required in a chiller system:

Evaporator – this is where the extracted process water enters the chiller system. Through the use of refrigerant, it is transformed into a low-pressure gas.

Compressor – in this part of the cycle, the compressor takes the low-pressure gas and turns it into high pressure, which in turn allows it to flow through to the next step, the condenser.

Condenser – the high-pressure gas is cooled by the condenser, whereby it converts back to low-pressure liquid form.

Expansion Valve – as part of the final step in the process, the liquid returns to the expansion valve and is directed back to the evaporator. The cycle can now begin again.

The Efficiency of Evaporative Cooling Systems

Water chiller systems utilizing cooling towers offer a cost-effective method of heat removal and interior temperature control of just about any type of facility, including industrial process operations. One of their primary advantages over other types of cooling systems is that they can achieve considerably lower water temperatures during the process versus other methods, such as air cooled systems, or systems involving dry heat rejection.

The water-driven system results in higher energy efficiency and overall lower cost of operation. Air-cooled chillers, for instance, may require more electricity to operate at similar volumes of cooling.

Optimization of Chiller System Performance

Chiller systems consume large amounts of energy to operate. Statistics show, in fact, that chiller use consumes about a fifth (20%) of all the electricity produced in North America. Clearly, there is room for optimization in the operation of these systems – estimates show that many systems consume 30% more energy than optimal – a considerable waste, and enormous unnecessary expense to building operations.

Potential areas of improvement to energy efficiency in chiller systems include:

- Optimizing chilled water set points

- Improvements to chiller sequencing

- Ensuring proper load balancing

- Peak demand and cooling tower water management

The emergence of the Internet of Things (IoT)-based technology has allowed for the development of excellent tools for chiller optimization. Real-time monitoring of performance and energy consumption, from each component within the system, is now available.

Additionally, IoT control advancements have proven to result in better control of temperatures during the supply and return phases of operation between chiller and cooling tower. These innovations can improve overall performance and lower energy consumption during the operation of just about any type or size chiller system, whether new or existing.

Different Types of Chillers for Industrial Use

Chiller systems are used in many industries for interior temperature control. They become vital especially in industries where operations and processes generate excess amounts of heat. In order to keep machinery and equipment running properly, and to provide personnel with proper interior working conditions, the reliable ongoing removal of this heat is needed, in the most efficient way possible. Chiller systems effectively achieve this goal.

There are different types of chillers in use for commercial, industrial, and institutional settings of many kinds. Here is an overview of them, and some of the advantages and disadvantages of each.

The Different Types of Industrial Chillers

There are three main types of industrial chiller:

- Water-cooled chillers

- Air-cooled chillers

- Evaporative-condensed chillers

Each performs exactly the same function – removal of heat from a building, resulting in lower interior temperatures. They share some of the same components, especially the condenser, but the methods of achieving heat removal within the condenser differ.

Water Cooled Chiller

Water-cooled chillers utilize an external cooling tower to provide water that cools the refrigerant, in gaseous form, within the condenser. Upon expelling its heat, the refrigerant is converted back to liquid, where it can once again be cycled through the phases to gaseous form, and back to liquid again.

Advantages of Water Cooled Chillers

In general, water-cooled chillers are more efficient to operate, when compared to air-cooled systems. They are very flexible and can be scaled to large size capability, as well as small-scale cooling requirements. Facilities that have issues with space constraints can also take advantage of portable water-cooled chiller systems. Another advantage to consider is their relatively quiet operation when compared to other types.

Disadvantages of Water Cooled Chillers

On the downside, because of the necessity for components such as the cooling tower, and water pump, water-cooled chillers can be more expensive, both to install and maintain than other systems. The ongoing requirement for water may also be an issue in some areas. An ongoing regimen of maintenance is required for these systems, to prevent breakdown from the accumulation of mineral deposits drawn out of the continuous cycling of the water.

Air Cooled Chillers

As the name in plies, air cooled chiller systems utilize the ambient air, with the help of fans, to dispel heat from the refrigerant in the condenser. The use of air to achieve this heat removal process, before the condensation step and back to recirculation is the major difference between them and the water-cooled version. The discharged heat from this type of chiller can be considerable at its location.

Advantages of Air Cooled Chillers

The upfront cost of the installation of an air-cooled chiller system tends to be less than its water-cooled counterpart. This is because they do not require components such as the cooling tower and water pump. They also tend to be less expensive to maintain for this same reason. They are a good recommendation when space constraints are an issue, and come in portable versions. In some setups, the ejected heat from the heater is used to warm the building interior during cold months. This can help offset heating and energy costs.

Disadvantages of Air Cooled Chillers

Air cooled chiller systems tend to be more energy-intensive to use, owing to the need for fan power which requires additional electricity use. They can also be louder, which can become an issue in certain types of interior settings. The overall service life of air cooled chiller systems can be somewhat less than water cooled versions.

Evaporative Condensed Chiller

An evaporative condensed chiller is an alternate method of achieving the same result of all chiller systems – converting refrigerant from a state of heated vapor to one of a cooled liquid. In lieu of the cooling tower of a water cooled chiller system, an evaporative condenser is used. It is somewhat of a hybrid system, sitting between an air-cooled condenser and its water-cooled counterpart.

The refrigerant in this configuration is converted from vapor to cooled liquid through the evaporation of water, which is sprayed on the outside surface of the tubing that holds the refrigerant. The elimination of the cooling tower found in the water cooled configuration reduces the number of steps from two to one – there is no trip to the cooling tower.

Advantages of Evaporative Condensed Chillers

Evaporative condensers have an advantage over air-cooled chiller units in that they can run on lower fan speeds – a savings of energy. Having fewer components, installation costs, as well as maintenance costs may be lower with evaporative condensed systems – there are fewer components involved. They are also relatively compact, which can be a benefit where space restrictions exist.

Disadvantages of Evaporative Condensed Chillers

Evaporative condenser chiller systems operate most effectively in hot, dry climates. Therefore, they may not be an appropriate call in cooler northern climates, for instance. All specifications for their use should be checked in advance of consideration. Other systems face fewer limitations in this regard.

Vapor Compression Versus Vapor Absorption in Chiller Systems

One further distinction in chiller systems is how the refrigerant is moved through the stages.

Vapor Compression Chillers involve the use of a compressor pump to transport the refrigerant; it subsequently extracts the heat out of the process.

Vapor Absorption Compressors, by contrast, involve no compressor, but rather the use of an absorber – a heat source that is used to transport the refrigerant through the system. The heat source itself is heated by either water or steam.

The Differences between Air-Cooled Chillers and Water Chillers

The role of any type of chiller system is simple: to remove excess heat from a building interior. It is an important component of any facility’s Heating Ventilation and Air Conditioning design, including:

- Industrial – factory, manufacturing, processing environment

- Commercial – shopping center, office complex

- Institutional – school, university

- Medical – hospital, laboratory

- Residential – condominium, apartment complex

There are a number of considerations that should be considered when deciding on which type of chiller system is best for a particular facility. These include:

- Total cooling requirement – BTU

- Climate, environmental concerns

- Physical space available

Once these basics have been identified, the choice of chiller type boils down to:

- Water Cooled Chiller

- Air Cooled Chiller

Following is a summary of the differences between these two dominant types of chiller systems.

Installed Cost

Air cooled chillers are generally installed at a lower cost than water cooled chillers, mainly because there is no requirement for a cooling tower, or condenser water pumps that keep the system circulating.

Life Cycle Cost

Water Cooled Chiller systems operate at a lower cost over the long term. This is owing to the fact that there is less energy required for air movement via fans, which air cooled chillers rely on. It should also be kept in mind that an air cooled chillers total life expectancy is less than water cooled chillers.

Ongoing Maintenance Requirements

Water cooled chillers require more frequent maintenance, mainly due to the fact that the continuous flow of water can cause scale, mineral deposits, and corrosion to the components, particularly on the cooling tower. While air cooled chiller systems require less maintenance, they are likely to deteriorate and require full replacement sooner than water cooled chillers.

Size of Installation

Smaller-sized chiller systems are most frequently air cooled, for cost reasons – the upfront extra installation costs associated with water cooled systems are not offset, despite their lower operating cost.

Large chiller installations are for the most part exclusively water-cooled; their lower long-term operating cost, coupled with a long history and familiarity gives them preferred status with most HVAC engineers and designers. The fact that water has superior heat transfer properties over air cooled chillers, particularly film coefficient, which controls heat transfer during the process.

In context, an air cooled chiller would require much more space than a water cooled chiller to achieve the same capacity as a water cooled chiller unit; thus their more limited use in larger sized chiller systems, despite the fact they do not require a cooling tower and condenser pump.

Overall Performance

Water cooled chillers provide superior cooling on a square foot basis, largely owing to the heat transfer qualities of water over the air, as previously mentioned. An additional consideration is the noise level associated with each type of system. Air cooled chiller systems, due to the frequently running motors and fans, are considerably noisier in operation than water chiller units. This should be taken into account at the design stage – the immediate surroundings near the equipment and the proximity to occupied space e.g. densely populated downtown residential areas.

Evaluating Water Cooled Versus Air Cooled Chiller Systems

Once these important differences between water cooled and air cooled chiller systems have been identified and factored in, the engineer or designer must decide which type is the best fit for any given installation. The major decision points must be assessed include:

- Overall anticipated system costs – including installation and running cost

- Size of the HVAC unit – as mentioned, smaller ones are typically air cooled, and larger ones most often water cooled

- Ambient conditions at the specific location – both dry bulb and wet bulb, anticipated hours of operation, maintenance costs, part load values

- Life cycle cost – which must include anticipated maintenance, breakdown, and repair costs, coupled with daily running costs

Installation Considerations – Potential Factors

There are certain drawbacks within both water cooled and air cooled chiller systems which can result in a knockout factor, even if they are the preferred choice by designers. These include:

Water availability considerations – the local cost of water, or its general scarcity in a particular location or region, may negate the option of a water cooled chiller system. Scarcity or lack of water means higher water costs, which makes the choice impractical from an economic standpoint. This factor is not uncommon in many parts of the world and should not be overlooked at the evaluation stage.

Night-time dry bulb (ambient) temperatures – in areas where the night-time bulb temperatures are much lower than daytime, an air cooled chiller can capitalize on the night-time plunge in ambient conditions, resulting in lower running costs. This of course particularly applies to situations requiring 24-hour running applications.

Space considerations – there are times where scarcity of space gives air cooled chillers the edge over water cooled chillers. With no need for a water cooling tower or mechanical room, they can be installed in tight quarters, including on the ground.

Air recirculation requirements – obstruction to continuous airflow will have a severely negative impact on the performance of air cooled chiller units. This becomes especially important when considering the location of the installation – high walls and other buildings or structures close by could all be an impediment to the airflow required for an air cooled chiller system to work properly.

Which is Better – Air Cooled Chiller or Water Cooled Chiller?

The answer is fairly obvious – there is no one system that is better. Engineers, technicians, and designers must take into account all the specifics previously mentioned. Every situation and location will be different. Generally speaking, water cooled chiller systems offer more efficient cooling, offset by higher maintenance costs associated with continuously flowing water through them.

The answer to “Which is better – air cooled chiller versus water cooled chiller” must be: It all depends.

Types of Process Cooling Applications for Industrial Chillers

There are many uses and applications for industrial chiller units across the spectrum of interior environments. Many processes in the industry, for example, create large quantities of excess heat which must be removed, both for the building occupants’ sake, and very often for the processes being conducted themselves. In other settings, very rigid standards apply to the consistency of indoor temperatures, which chiller units can help control. For very large commercial facilities, industrial chiller systems greatly aid in HVAC system performance involving very large square footages of interior space.

Following is a summary of specific types of process cooling applications for industrial chillers.

Power Generation

Power generation facilities producing electricity produce large amounts of heat during their processes. Industrial chillers are used to cool equipment and surroundings of gas turbine power generation stations. Biogas plants also make use of chillers to cool down biogas, dehumidifying it at the same time, as a way of controlling corrosion and damage to the internal combustion engines the product is used in.

Industrial Medical

Many machines and instruments in the medical industry rely on closely controlled temperature ranges for the equipment to function properly. Large size medical machinery, such as MRI and CT scanners, produce heat that cannot be allowed to over-accumulate. The use of chillers ensures that excess heat is removed and the instruments and processes stay working as intended.

Working Conditions in Industrial Settings

Very often, the manufacturing floor requires the removal of excess heat generated by operations, for the sake of employees working in that environment. Unaddressed, continuously rising interior temperatures could render the working conditions both uncomfortable and indeed unsafe for anyone on that shop floor. Chillers are employed to draw the undesired heat away from the manufacturing area and maintain working temperatures at an acceptable level. Coupled with air handling equipment, chillers can function like air conditioning units, supplying cool air to the facility interior.

Industrial Equipment Cooling

Within many industrial processes, furnaces, ovens, high-power equipment, and friction-utilizing operations can produce copious amounts of excess heat. The heavy-duty equipment is often maintained with cooled liquid via chillers, maintaining appropriate temperatures so that the equipment can continue to run efficiently and without breakdown.

Plastic Manufacturing

Chillers are used in the plastic manufacturing process, as a means to control optimum temperatures during the processing of the sensitive material. The molds the liquid plastic is set into require carefully controlled temperature ranges. Heat exchangers ensure the water from the process of extrusion remains separate from the cooling water. A quality finished product in the plastics industry relies on the carefully calibrated temperatures that chiller units ensure.

Metal Plating Industry

Extreme temperatures are created during the bonding of coatings and other processes in the metal plating industry. Some of these include:

- Anodizing metal

- Laser cooling

- Spot welding

- Furnace cooling

- Die casting cooling

- Paint and powder coating

Heavy-duty chillers are required during such processes. They remove the heat from the processed metal, which ensures a quality bond to the substrate. Different techniques and methods are used for each specific process; chillers play a vital role in each.

Industrial Welding Processes

Certain welding processes also require chilled water to cool down the welding torch, especially those involved in robotics welding processes.

Concrete Batching Processes

Chilled water is also used for certain concrete batching processes. In order to increase the strength of the concrete, the concrete temperature must be at at lower temperature point. For these situations, chilled water is used to batch the concrete. This is a very common application during the construction of very large concrete structures.

Biogas Processes

For biogas process, chiller will act as dehumidifier to remove the moisture content in the biogas.

Chemical and Paint Processing Lines

For chemical or paint processing line, chilled water is require to maintain the product temperature especially during reaction process.

Food Production and Storage Facilities

Perishable foods and, in fact, foods and ingredients of all kinds are subject to strict guidelines and regulations regarding storage temperatures. Whether at the processing facility or at the warehousing or distribution end, chillers are used to help ensure the correct interior conditions are achieved and maintained. Many of these units are specialized so as to prevent the possibility of food contamination. This includes potable water chillers, along with chillers using non-toxic propylene glycol, for the safest possible conditions when dealing with this sensitive product.

Pharmaceutical Production and Storage

The production and manufacturing of many medicines require tight temperature ranges and precise control. Chilled water is often used during such processes. Chillers with this type of accuracy are utilized in such instances. There are various types of chillers used, including absorption, reciprocating, centrifugal and screw-driven chiller systems. There are units used for central process purposes, as well as smaller compact process chilling units. They have proven essential for the pharmaceutical industry.

Laser Processes

Chillers are often used in the laser industry. The sensitive equipment used in this unique industry, including high power exciters, ion lasers, and CO2 lasers, requires continuous, strict temperature control in order to maintain precision and accuracy, and perform at optimal efficiency. The reliability of chiller water cooling systems is the solution for this type of critical requirement.

Chiller Systems for Temporary Use

Large construction projects often use portable, temporary Heating, Ventilation & Air Conditioning (HVAC) systems on site. They provide the temperature control required by the trades on site. These temporary systems are included within contractor bids, as a pre-planning feature and line-item inclusion. There are several reasons why such a temporary system is needed during a construction project, including:

Dehumidification, heating – especially during new construction during cold seasons, when a permanent system may not yet be up and running. There are also specific situations where dehumidification is needed during a project; for example, data center installation.

Ventilation – a temporary HVAC system is frequently required to maintain negative pressure on a worksite, or for circulation of air when smoke is involved.

Air conditioning – during hot summer months, cooling is often required on a construction site, where permanent equipment is not yet in place, or has failed.

These are a few of the most common uses for industrial chillers. They play a vital role where consistent, reliable temperature and humidity control is required during processes of many types.

Best Practices for Maintaining Industrial Chillers

Industrial chiller units, whether water cooled or air cooled, work hard at their job. They extract excess heat from whatever source they are tied into, whether it is the indoor climate of a manufacturing plant or an MRI unit in a hospital. They are a vital, valuable, if not indispensable piece of equipment, and as such, it only makes sense that they be kept running as efficiently and effectively as possible, for as long as possible. There are several ongoing preventive maintenance items that should be addressed on an ongoing basis, to maximize performance and the service life of an industrial chiller unit.

Preventive Maintenance Items for Industrial Chillers

Keep a log – this is a great discipline to get into for keeping your chiller unit running in top condition at all times. A daily check and recording of its operational status including:

- Fluid levels

- Flow rates

- Temperatures

- Pressures

There are paperless ways of this record-keeping process as well. Several apps are available which allow for an automated way to keep a log up to date on a mobile device.

Maintain clean heat transfer – the chiller’s efficiency relies on it. If contaminants are allowed to gather, including:

- Scale

- Algae

- Mud

- Mineral deposits

- Impurities of any kind

The result is increased thermal resistance. This in turn reduces the overall performance of the chiller unit. A good way to measure heat transfer efficiency is the approach temperature of the water flow. The higher the approach temperature, the lower the efficiency. Annual maintenance of condenser tubes should include thorough brushing out of all contaminants, such as those just listed. Higher demand units should be cleaned out even more frequently, as required.

Condenser water treatment – corrosion, algae, and scale are all greatly reduced if the water is treated. Overlooking this maintenance item runs the risk of condenser water loops contributing to clogging and an overall decrease in the effectiveness and efficiency of movement through tubes and piping. Chilled water loops should be inspected annually or more dependent on use, for evidence of corrosion and debris buildup. Water monitoring can be done remotely, and adjustments made as necessary.

Lower the temperature of entering water – the lower the temperature of the entering condenser water, the greater the efficiency of the chiller process. Note that dirty coils in an air handling unit can also impede efficiency. Lowering condenser water temperature is not a solution. The chiller simply has to work harder, while achieving the same amount of cooling.

Maintain the chilled water flow rate – the optimal range should be 3 feet per second (FPS) to a maximum of around 12 FPS. If the flow rate is too low, chiller efficiency is compromised and often results in undesired laminar flow. Flow rates in excess of 12 FPS can result in vibration and noise issues. Tube erosion can also be a consequence. A consistent chilled water flow rate is best for both efficiency and upkeep of all components within a chiller system.

Keep the proper levels of refrigerant – this is critical to achieving the desired amount of cooling in the chiller system. Decreasing levels of refrigerant are usually the result of leaks within components, as well as the entry of air and moisture into the system. The consequence is decreased efficiency – the compressor is forced to work harder, with less cooling effect. Monitoring refrigerant regularly, and repair of any leaks or deterioration of parts is essential to ensure proper levels.

Have the compressor oil analyzed – this should be done annually at least. Spectrometric chemical analysis may reveal issues such as high moisture within the compressor oil. Oil filters should be checked, and replaced if deficient. Low-pressure chillers generally require more frequent oil checks – this should be based on purge hours.

Check all the electronic components – starters, motors, electrical connections, wiring, switchgear, insulation resistance – all should be checked regularly. Safety controls, and sensor calibrations should be checked according to the manufacturer’s guidelines. Inspect connections for worn contacts and hot spots.

Open drive motors should be inspected – for refrigerant leakage at the shaft seal. Motor cooling air vents need to be cleaned regularly for maximum flow. All electronic components play an important role in the operation of any chiller system; they should not be overlooked and should be part of any regular maintenance schedule and program.

Consider variable speed drives – the best way to reduce energy consumption, and indeed wear on electric motors within a chiller system is to install variable speed drives (VSD) where possible. Matching motor speed to load is an excellent way to consume less energy during the chiller process. It is important to note that a chiller motor can be the single largest electrical load of a facility.

The “soft starter” attribute of VSDs also serves to lower the inrush current on the motor. The reduced mechanical shock to a system when starting high power motors is beneficial to both chiller reliability and its ultimate service life.

Maintenance Items for Air Cooled Chillers

Air cooled chillers come with some maintenance considerations specific to their configuration:

Inspect cooling coils regularly – they should be checked for signs of corrosion and distortion in fins. Leaving them unaddressed will negatively impact chiller performance.

Condenser fan inspections – belts and couplings should be inspected and adjusted as necessary, to maximize efficiency and performance. Emphasis should also be placed on the condition of bearings – wear and lubrication.

Condenser coils – inspect or kinking, blockage, as well as corrosion of the coils, and leaks areas.

Return air dampers – an important component of air cooled chillers, they should be checked regularly to ensure optimal operation. Their calibration should be carried out in conjunction with the above maintenance of bearing alignment, lubrication.

Fresh air dampers – a similar regimen of inspection and maintenance should be adopted for these components, similar to the return air dampers.

The Last Word – Always Choose Quality Industrial Chillers

Throughout our discussion, we’ve highlighted the complexity of HVAC and the critical role industrial chillers play in high-demand cooling systems. They serve a wide cross-section of industries and uses. Industrial chillers come in a variety of sizes, capacities, and configurations, including:

- Water cooled chillers

- Air cooled chillers

- Evaporative condensed chillers

When determining what’s best for any given HVAC situation, it is highly recommended you consult with an expert in the field. They can assist with the selection of the right chiller system, which will fit the specifications and needs of the application. It is important to remember quality during the evaluation process. Better industrial chiller units deliver problem-free service for much longer than “bargain” alternatives.

Amcon would be pleased to discuss your specific HVAC and industrial chiller needs. Contact us to learn more.