Manufacturing of Air-Cooled Chillers

Table of Contents

Industrial Air-Cooled Chiller Built in Malaysia for Heavy-Duty Cooling

Amcon has been distributing Air Cooled Chillers in Malaysia since 1988 solely as a distributorship, fast forward to today, Amcon has 2 manufacturing plants located in China and Malaysia, with a manufacturing capacity of 700 units per annum. Amcon offers various air-cooled chillers and spare parts to suit process cooling requirements. Aside from Amcon’s manufacturing of air-cooled chillers, Amcon also provides rentals, refurbishing and customizations chillers that includes multiple piping connection options for different site installation requirements.

When choosing the type of chiller, air-cooled chillers are generally sufficient enough compared to water-cooled chillers for smaller-type systems. The initial setup cost for an air-cooled chiller is also significantly lower and helps in saving space. As for electrical consumption however, air-cooled chillers consume more power, at an average of 1.1kw/ton, while water-cooled chillers consume an average of 0.75kw/ton. Since the initial setup cost for air-cooled chillers is significantly lower, therefore for smaller systems, air-cooled chillers are more suitable and practical.

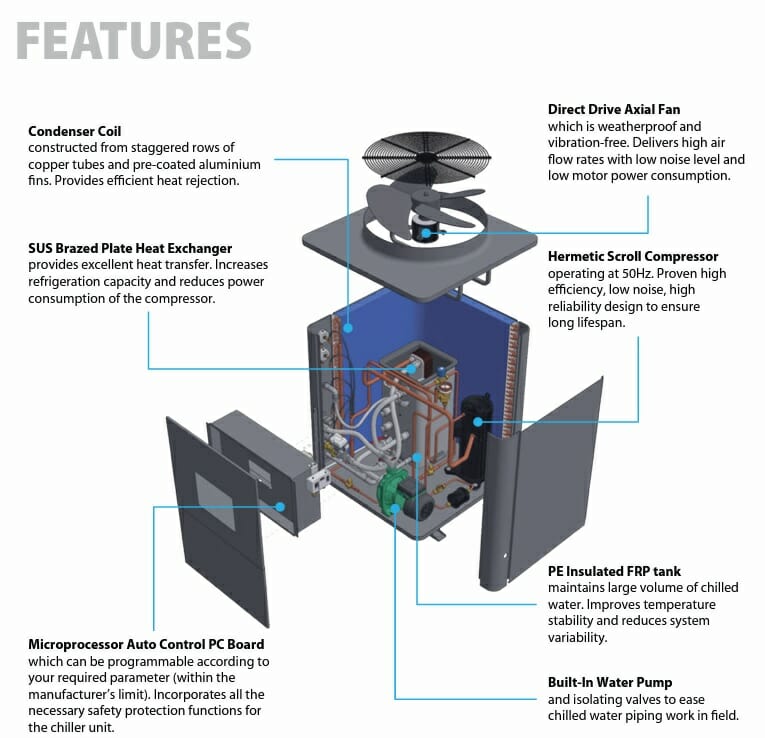

Amcon uses only the best quality components in the manufacturing of air-cooled chillers, as seen below:

Air Cooled Chiller Features

New Air-Cooled Chillers

To ensure the accuracy of the chiller size, customers are requested to provide the required water flow rate and inlet/outlet water temperature. Amcon’s sales representatives can provide free consultation on the correct size of chillers based on your cooling process requirements.

The time it takes to deliver, assemble and install an air-cooled chiller depends on the chiller size. For smaller air-cooled chillers such as the AMC030AC-B-1, it may take up to 3 days, while a larger air-cooled chiller such as the AMC300AC-B-2, can take between 7 to 10 days.

Amcon provides a 12-month warranty from the date of testing and commissioning, or 18 months after the delivery date, whichever comes first.

Refurbished Air-Cooled Chiller

10HP Air Cooled Chiller

– 10HP Scroll Type Compressors

– Alum Fin – Copper Tube Condenser

– SUS Brazed Plate Heat Exchanger

– Fully Refurbished like new unit

– 3-months warranty

Air Cooled Chiller Rentals

Temporary Cooling Solution

40HP rental unit perfect for short-term plant cooling and emergencies.

Custom Build Air-Cooled Chiller

- Food-grade (SUS Tank)

- Special Cooling Capacities

- Site-limited footprints

- FAQs

Air-cooled chillers are refrigeration systems designed for industrial and process cooling applications. They remove heat from water or process fluids by circulating refrigerant through a compressor and condenser. Instead of using water for cooling, these chillers use ambient air to reject the heat. This design makes them well-suited for smaller systems where space is limited, and water availability is a constraint.

AMCON’s air-cooled chillers are particularly beneficial for smaller system requirements due to their lower initial setup cost and compact installation footprint. While these chillers generally consume more power—averaging around 1.1 kW/ton compared to water-cooled chillers at 0.75 kW/ton—they save on infrastructure costs. Ideal for applications where installation space and upfront investment are limited resources, making them a practical choice for many industrial processes.

AMCON’s air-cooled chillers are commonly used in industrial water chiller projects, processing plants, and facilities that require reliable system cooling without the complexity of water-cooled installations. Their versatility and robust construction make them a popular choice for various industrial, manufacturing, and commercial applications throughout Malaysia.

AMCON operates manufacturing facilities both in China and Malaysia, ensuring a robust production capacity for air-cooled chillers. Depending on the chiller model and system requirements, smaller units (e.g., AMC030AC-B-1) can be delivered, assembled, and installed within up to 3 days. Larger units (e.g., AMC300AC-B-2) may require between 7 to 10 days.

To accurately determine the correct chiller size, customers are requested to provide key process data, including the required water flow rate and the inlet/outlet water temperatures. Contact us for free consultations and guidance based on these parameters, ensuring that the selected chiller will meet your needs.

Yes – refurbished units come with a 3-month coverage.

Yes, we offer stainless steel SUS tanks for F&B cooling applications.

Talk to Cooling Expert

Read more on Air-Cooled Chiller

- The Ultimate Guide to Industrial Chillers 2022

- The Ultimate Guide to HVAC & R Products and Specifications

- The Benefits of Using an Air-Cooled Chiller in Industrial Cooling Applications

- How to Properly Maintain an Air-Cooled Chiller to Ensure Maximum Efficiency

- The Energy Efficiency of Air-Cooled Chillers: A Review of Industry Standards and Best Practices

- The Latest Technologies and Innovations in Air-Cooled Chiller Design and Performance

- The History of Air-Cooled Chillers: From Early Beginnings to Modern-Day Technology

- The Selection and Sizing of an Air-Cooled Chiller for Any Specific Application: A Step-By-Step Guide

- The Maintenance and Upkeep of Air Cooled Chillers: 9 Best Practices

- The Cost-Effectiveness of Air Cooled Chillers: Balancing Initial Investment and Long-Term Operating Costs